As electric vehicles, energy storage systems, and portable power equipment continue to evolve, Battery Management Systems (BMS) are expected to deliver more than basic protection. Modern BMS designs increasingly require real-time visibility, remote access, low power consumption, and scalability—all without adding unnecessary system complexity.

Bluetooth® Low Energy (BLE) modules provide a practical and proven wireless communication solution for BMS applications, enabling smarter battery monitoring and more efficient system maintenance.

A BMS is responsible for continuously monitoring and managing critical battery parameters, including:

Voltage, current, and temperature

State of charge (SOC) and state of health (SOH)

Abnormal conditions such as overcharge, over-discharge, and overheating

Beyond data collection, system designers and end users increasingly expect:

Convenient access to battery status via mobile devices

Reduced wiring complexity and easier deployment

Support for remote diagnostics and firmware updates

These requirements make low-power, reliable wireless communication an important design consideration.

Conventional BMS solutions typically rely on wired communication, which can introduce several challenges:

Complex wiring: Cabling becomes difficult and costly in space-constrained or distributed battery systems

Limited accessibility: Data access is often restricted to physical interfaces, reducing usability

High maintenance cost: System expansion and upgrades are harder to implement over time

As BMS architectures grow more flexible and distributed, these limitations become increasingly apparent.

Integrating a BLE module into a BMS enables wireless data transmission without significantly altering the existing system architecture.

Battery data can be transmitted directly to a smartphone app or upper-level system, allowing users and maintenance personnel to monitor battery status anytime and anywhere.

BLE is optimized for low-power operation, minimizing additional energy consumption and preserving battery life over long-term use.

With strong anti-interference performance and a mature protocol stack, BLE ensures stable connections and sufficient data throughput for BMS monitoring needs.

BLE supports advanced encryption mechanisms to protect data transmission. OTA (Over-the-Air) firmware updates enable remote upgrades and feature enhancements, extending system lifespan.

In a common implementation, the BLE module is integrated into the Battery Control Unit (BCU):

The BCU handles data acquisition, processing, and high-voltage system management

The BLE module wirelessly transmits key battery data to a mobile app or backend platform

The upper-level system provides data visualization, alerts, and remote maintenance

This architecture improves usability and operational efficiency while maintaining system safety.

BLE-enabled BMS solutions are widely adopted across multiple industries where battery visibility, system reliability, and ease of maintenance are critical.

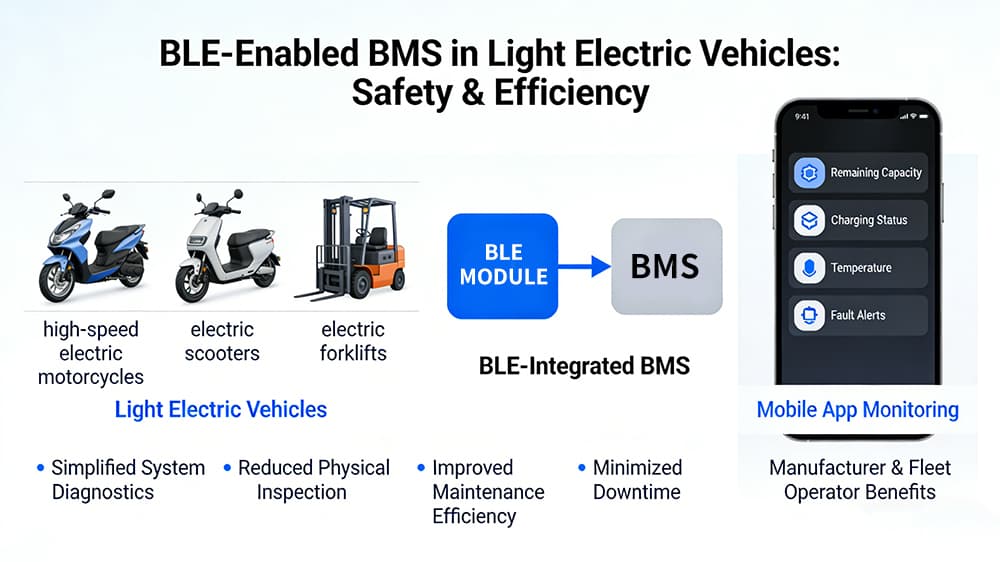

In light electric vehicles such as high-speed electric motorcycles, electric scooters, and electric forklifts, BMS performance has a direct impact on safety and user experience.

By integrating a BLE module into the BMS, users can monitor key battery parameters—such as remaining capacity, charging status, temperature, and fault alerts—directly through a mobile application.

For manufacturers and fleet operators, BLE connectivity simplifies system diagnostics and reduces the need for physical inspection, improving maintenance efficiency and minimizing downtime.

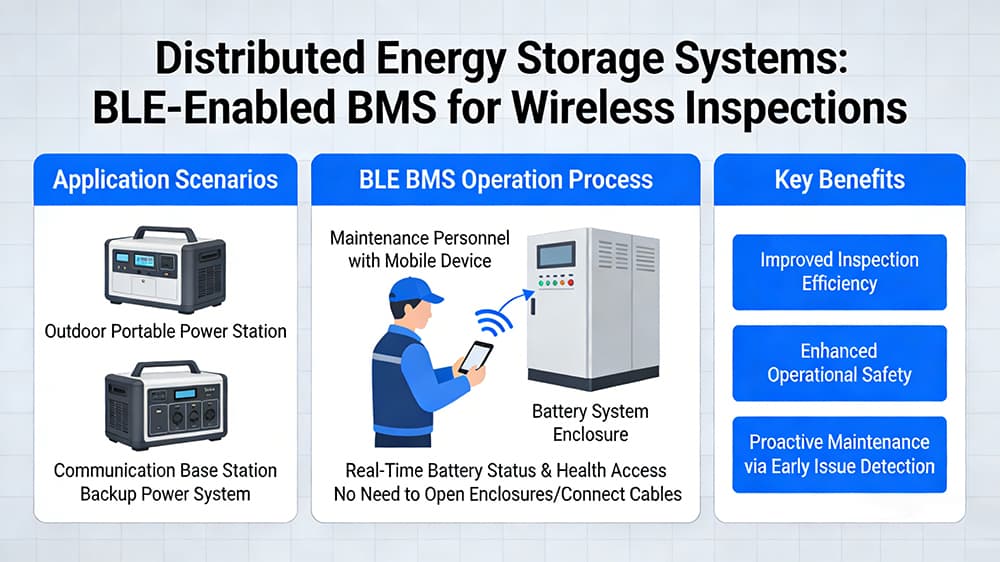

In distributed energy storage applications, including outdoor portable power stations and backup power systems for communication base stations, battery systems are often deployed across multiple locations.

BLE-enabled BMS allows maintenance personnel to perform routine inspections wirelessly, accessing real-time battery status and health information on-site without opening enclosures or connecting cables.This approach improves inspection efficiency, enhances operational safety, and supports proactive maintenance by identifying potential issues early.

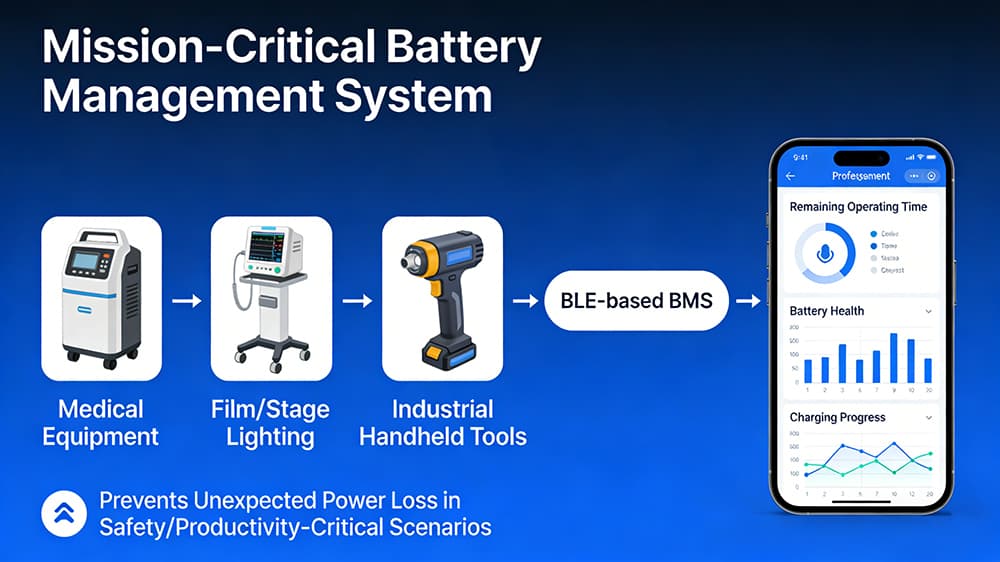

Portable professional devices—such as medical equipment, film and stage lighting systems, and industrial handheld tools—require accurate and reliable battery information to ensure uninterrupted operation.

With a BLE-based BMS, users can easily check remaining operating time, battery health, and charging progress from a nearby mobile device. This is particularly valuable in mission-critical environments, where unexpected power loss may impact safety, productivity, or service continuity.

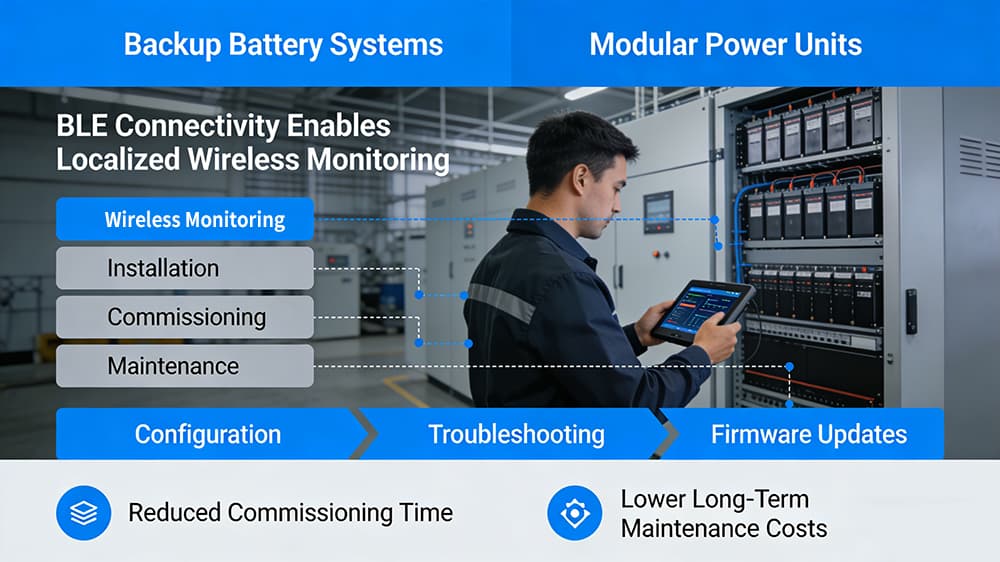

In industrial and commercial applications, including backup battery systems and modular power units, BLE connectivity enables localized wireless monitoring during installation, commissioning, and maintenance.

Technicians can quickly access battery data for configuration, troubleshooting, and firmware updates without additional interfaces, helping reduce commissioning time and long-term maintenance costs.

In a new energy vehicle BMS project, a customer integrated the ME54BS12 BLE module—based on the Nordic nRF54L15 SoC—into their system to enable real-time wireless battery monitoring.

This solution helped the customer:

Improve battery data accessibility

Enhance maintenance efficiency

Reduce overall system maintenance costs

Prepare the platform for future functional upgrades

As BMS solutions continue to advance toward smarter and more connected systems, BLE modules play a key role in bridging batteries with users and digital platforms. With their low power consumption, stable performance, and mature ecosystem, BLE modules offer a reliable wireless communication option for modern battery management systems.

By adopting BLE-enabled BMS architectures, manufacturers can improve battery safety, user experience, and long-term system scalability—without increasing design complexity.

Hot tag

Recommended articles